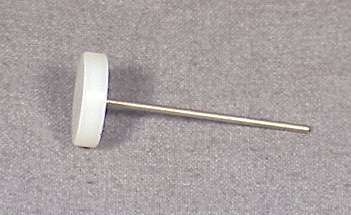

2) Locate the Displacer Plug [D2] and the Displacer Rod [D3]. Insert the Displacer Rod into the Displacer Plug and press or gently hammer the rod until it goes entirely through the plug, and is flush on the other side. It makes no difference which side of the Plug the Rod is pressed into. If you file the edge off of the Rod before you press it into the Plug, it may enter more easily, and it may scrape less plastic out of the Plug. This is the Displacer Plug Assembly. It is important that the Displacer Rod be at right angles to the Displacer Plug: if this is not so, gently bend the Rod until it is positioned correctly.

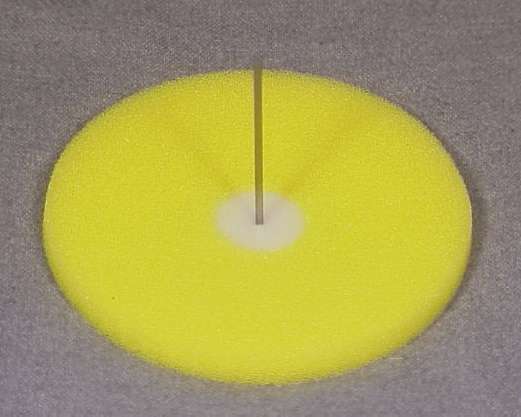

3) Locate the Displacer [D1] and Displacer Plug assembly. If you are using caulk or epoxy, apply a small amount of adhesive to the edge of the plug and press it into the inside of the Displacer. If you are using super glue, assemble the parts dry and then put three drops of super glue equally spaced around the Plug; then wipe excess glue off. After verifying the geometry of this assembly (see just below) set the Displacer aside to set/dry.

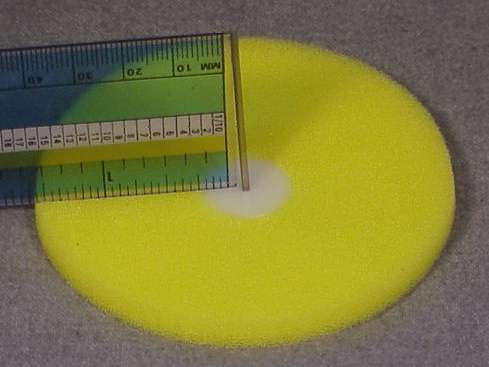

It is important that the Rod be at right angles from the Displacer and Plug. You can verify correct assembly using either a piece of paper or a ruler, as is shown in the following images. Rotate the Displacer and verify that the Rod is pointing straight up. If it is not, gently adjust the Rod or the Displacer until it is correct. You can also gently twirl the Displacer to verify that it is symmetrical. You can also drop the Displacer into the Crankcase (see below) to see whether the Displacer touches the Crankcase with one edge first (bad!) or evenly (good!).

Another way to verify the construction of the Displacer is to invert the Crankcase and insert the Displacer rod through the hole in the bottom (now the top) of the Crankcase. The Displacer will rest on the bottom (now the top) of the Crankcase. By pressing on the top (now the bottom) of the Displacer Rod, as it extends out of the copper tube, you can get the Displacer to sit about 3/8 of an inch above the Crankcase. You can then rotate the Displacer, and observe whether it is symetrical or not. Note that the Displacer does not rotate during normal operation: you should not worry if the Displacer wobbles when spun at high speed.